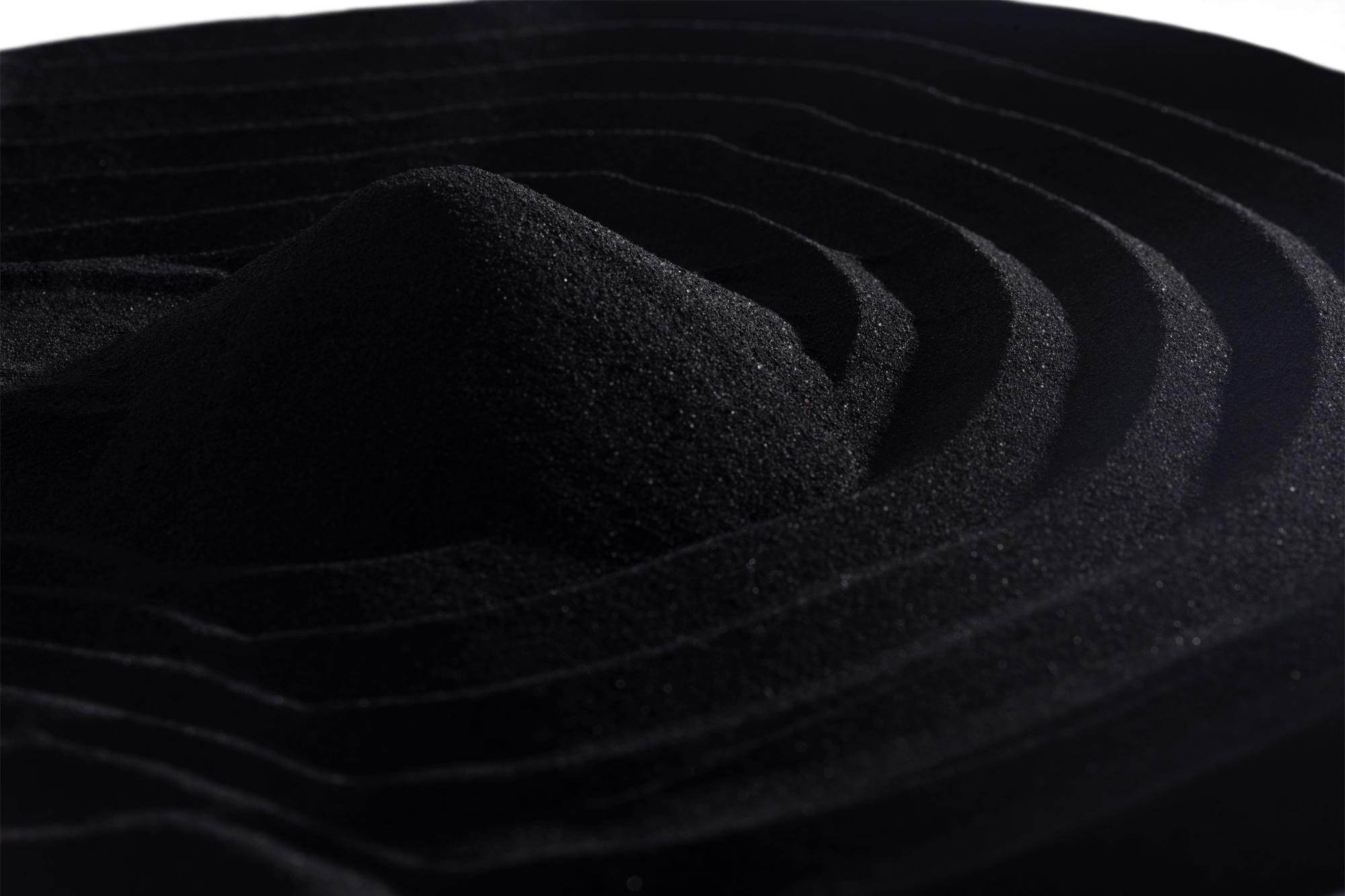

Synthetic Rutile

Synthetic rutile refers to a titanium-rich raw material produced by separating most of the iron components in ilmenite using chemical processing methods. It is similar in composition and structural properties to natural rutile, with TiO2 content fluctuating within the range of 87%-96% depending on the processing technology, making it a high-quality substitute for rutile.

Details